Clarifying and Nucleating Agents in Plastics: Benefits, Uses, and Market Importance

In modern plastic manufacturing, performance and efficiency are critical for staying competitive.

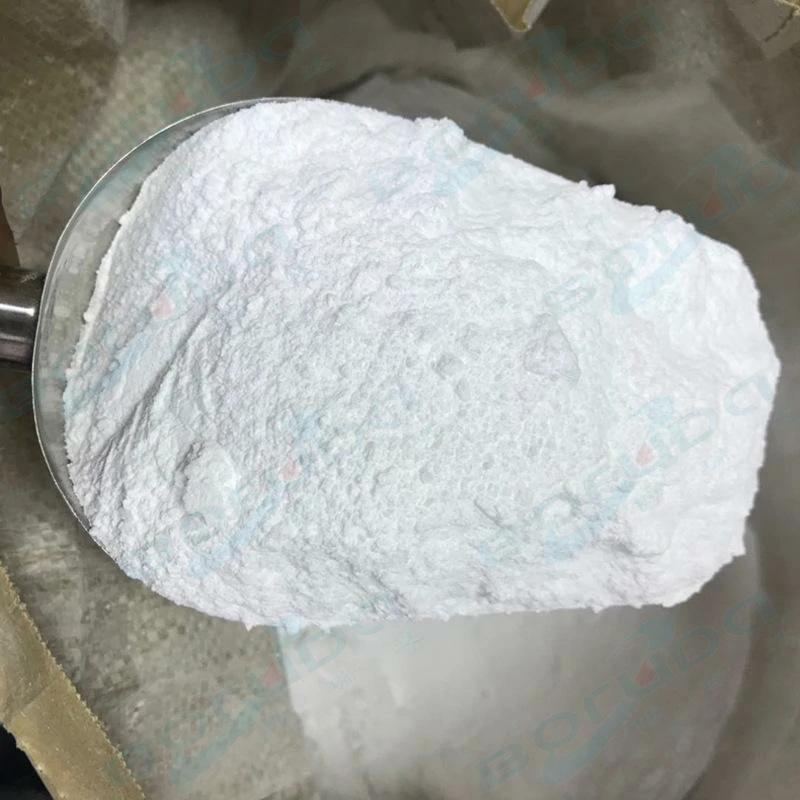

Clarifying and nucleating agents are advanced polymer additives designed to improve optical clarity, mechanical strength, and processing speed of plastics. These additives are widely used across industries where product quality, consistency, and cost control are essential.

For manufacturers and business owners, clarifying and nucleating agents offer a practical way to enhance product value while improving production efficiency.

What Are Clarifying and Nucleating Agents?

Clarifying and nucleating agents are additives used in semi-crystalline polymers to control how crystals form during cooling.

- Nucleating agents accelerate crystallization and create smaller, uniform crystal structures

- Clarifying agents further refine these structures to allow more light to pass through the material

Together, they help produce plastics that are clearer, stronger, and faster to manufacture.

Key Benefits of Clarifying and Nucleating Agents

Improved Optical Clarity

Clarifying agents significantly enhance transparency and brightness, making plastics visually appealing and suitable for packaging and consumer products.

Enhanced Mechanical Properties

Nucleating agents improve stiffness, strength, and dimensional stability, resulting in more durable and reliable plastic components.

Faster Processing and Higher Output

By reducing cooling and cycle times, these agents increase production speed, helping manufacturers improve efficiency and reduce energy consumption.

Consistent Product Quality

Uniform crystallization leads to better surface finish and reduced defects, improving overall product consistency.

Applications of Clarifying and Nucleating Agents

Clarifying and nucleating agents are used across a wide range of industries, including:

Packaging Industry

Used in food containers, bottles, and rigid packaging to achieve high clarity, strength, and aesthetic appeal.

Automotive Industry

Applied in interior and functional components where dimensional stability and mechanical performance are essential.

Medical and Pharmaceutical

Used in trays, syringes, and diagnostic products that require clarity, precision, and compliance.

Consumer and Household Products

Improve the appearance and durability of storage containers, appliances, and everyday plastic goods.

Business Advantages for Manufacturers

From a commercial perspective, clarifying and nucleating agents deliver measurable value:

- Reduced production costs through faster cycles

- Increased output without additional equipment

- Improved product differentiation and brand value

- Lower rejection and waste rates

These advantages make them a strategic investment for manufacturers focused on long-term growth.

How to Select the Right Additive

Choosing the right clarifying or nucleating agent depends on:

- Polymer type

- Desired clarity and strength

- Processing conditions

- End-use requirements

Selecting high-quality additives ensures consistent performance and regulatory compliance.

Clarifying and nucleating agents play a vital role in modern plastic manufacturing by improving clarity, strength, and processing efficiency. Their ability to enhance both product performance and operational efficiency makes them indispensable across packaging, automotive, medical, and consumer industries.

For business owners and manufacturers, adopting the right clarifying and nucleating agents is a smart step toward producing high-quality plastics while maintaining cost efficiency and competitive advantage.